Innovation at Vandersanden: How RoboBrick was created

As a traditional brick manufacturer, it may seem at odds to our ethos to introduce a fully automated machine that can lay strips of bricks and create intricate patterns all in one go? However, RoboBrick fits seamlessly into our innovation strategy.

We think it is important to constantly question ourselves. Vandersanden is always looking to the future, even generations ahead and that requires us to be aware of shifts that have a major impact in the long term.

4 trends with a major impact in our sector

Today, we are seeing four trends that are having a major impact in our sector. The first is scarcity. The European construction sector is suffering from tighter production capacity, partly due to a growing labour shortage, both in numbers and in quality. This is at a time when the economic growth of recent years has led to a rising demand for housing. Housing scarcity is, therefore, the second megatrend.

The BBC's Housing Briefing estimates that in the UK we have built 1.2 million fewer homes than we should have, and the need for more homes is increasing. The calculations suggest it will take at least 15 years at current building rates to close the gap, and that not enough of what is being built is affordable.

Not only is demand growing, understandably the list of requirements for new construction products is also constantly increasing. Construction manufacturers are faced with more and more stringent directives in the areas of product quality, ecology and safety.

Climate-neutral strategy 2050

Finally, you have the renovation market. If the UK wants to realise its long-term 2050 climate-neutral strategy, there is still much to be done. In September, the UK Government announced that homes, schools and hospitals across England are set to be greener and cheaper to run thanks to a £3 billion plan to upgrade the nation’s buildings – the biggest in a generation. This is a start, it’s a great challenge, but, above all, a great opportunity for construction.

Prefab is (part of) the answer

Part of the answer to these challenges will be prefabricated. The many advantages of prefabrication are:

- Fewer failure costs

- Fewer movements on the construction site

- Less transport

- Better quality

- Automated assembly control

- Safer: working without scaffolding

- Guarantees

- Speed, minimum construction site time

One in three projects in Europe already uses some form of prefabricated elements today. These can be sandwich panels, floors, complete facades, but even complete prefab kitchens or bathrooms.

According to Forbes, during the 2017-18 period, only 7.5% of the homes built in the UK used prefabricated or modular elements compared to 15% in Japan, 20% in Germany and an immense 84% in Sweden. The UK is lagging behind other parts of the world and there is a huge opportunity to catch up.

Save 15% of costs

Today, prefabrication is still almost as expensive, but through further robotisation, digitisation and complete coordination of the entire building process, prefabrication can save at least 15% of costs compared to conventional construction.

It is, therefore, quite clear that the construction market will be seriously disrupted by prefabrication, industrialisation and robotisation.

Our approach is not to wait, but to take the lead in this andRoboBrick is a logical answer.

You can't do a little prefab

If you really want to industrialise the building process, you have to see the whole process from a prefabricated perspective.

All aspects of the construction must be geared to each other, from design to assembly. The earlier people take prefab into account in the design, the greater the profit and the quality of the end result. Prefabricators are also increasingly engaged in far-reaching integration. This is the only way to maximise the benefits of prefabrication. In concrete terms, a prefab builder of facade elements will deliver his walls including connections, windows and facade finishing.

RoboBrick

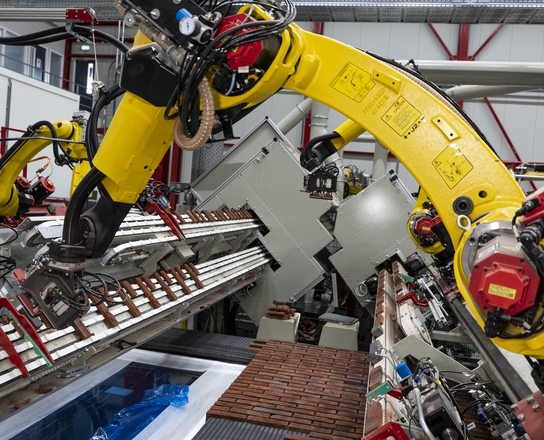

This is where the RoboBrick comes into its own. As a partner for facade finishing, with a great deal of expertise in brick (strips) but also in gluing, we want to be able to offer our partners a total solution. This is why we developed - partly through intensive co-operation with clients, such as, Spaansen and IIbo - a facade system that is seamlessly integrated into the prefabricated production process. RoboBrick applies stone strips to prefabricated systems or walls in an automated manner and in a specifically conditioned room. It connects to an existing or new production line and works on all kinds of substrates, such as, timber frame, steel construction, concrete or insulation material. The system enables us to glue no less than 2000 stone strips per hour, fully automated. But just gluing strips is not enough in a real prefab process.

Brickdesigner software voor de juiste strip op de juiste plek

We also provide dimensionally stable stone strips, which are packaged in such a way that they can be stacked automatically. If your supply cannot keep up with the speed of your machine, it is no use to you.

We have also noticed that our customer spends a lot of time drawing out each strip. For this reason, we’ve developed the brickdesigner software. This software draws each adhesive strip and each stone strip on the wall, taking into account the different windows, doors, walls, tolerances and, of course, the required bandages. The software controls the RoboBrick machine so that the right strip is always glued in the right place and in the right way.

20 jaar productgarantie

All critical production data is measured via numerous sensors and checked by a local control PC. If all the data is in order, the customer receives a warranty certificate. The information can be reviewed at all times as each prefabricated element has an RFID tag built into it that allows the production of the panel to be tracked right through to construction, and afterwards. This enables us to link all the panels to the critical production data, and therefore also the certificate of guarantee. It means that Vandersanden can offer clients a 20-year guarantee.

So that's why we designed RoboBrick. As a brick manufacturer, it is simply the best answer to the questions that come from our partners. At pivotal moments like this, when the entire construction sector is transforming, we want to be the partner of choice in the industry to work with because we believe that we make the most beautiful things when we work together.

Would you like to know more about RoboBrick?