Moulded or extruded?

Vandersanden offers two types of sustainable clay paver – moulded and extruded. The two types differ in production method, giving them different properties. What are the differences, and how should you choose?

Moulded

The moulded brick is by far the most used clay paver in the Netherlands. They are formed by compressing clay into moulds in our state-of-the-art plants in Tolkamer and Spijk. The mould is turned after being compressed, so that the brick can fall out and dry. After drying, the brick enters the kiln.

It’s this method of production that gives a moulded brick its natural appearance. Our moulded bricks are untumbled as standard, but can also be supplied as a tumbled variant. You can also opt for a sand-covered or unsanded variant. The stones are available in a wide range of sizes, including the familiar waal, dik, and kei sizes as well as our own Linge® size. Stones in waal and dik size are also available with spacers.

Moulded range

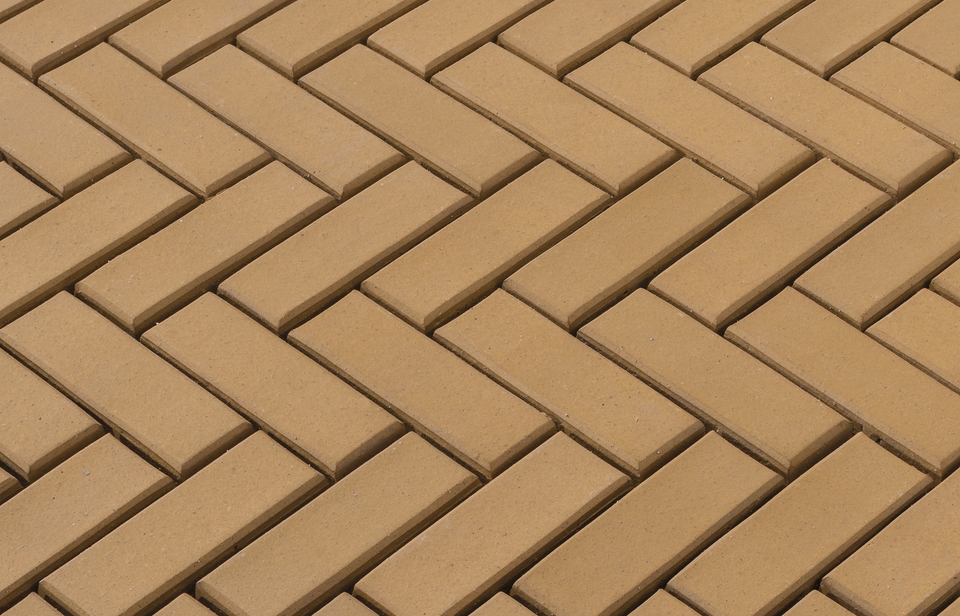

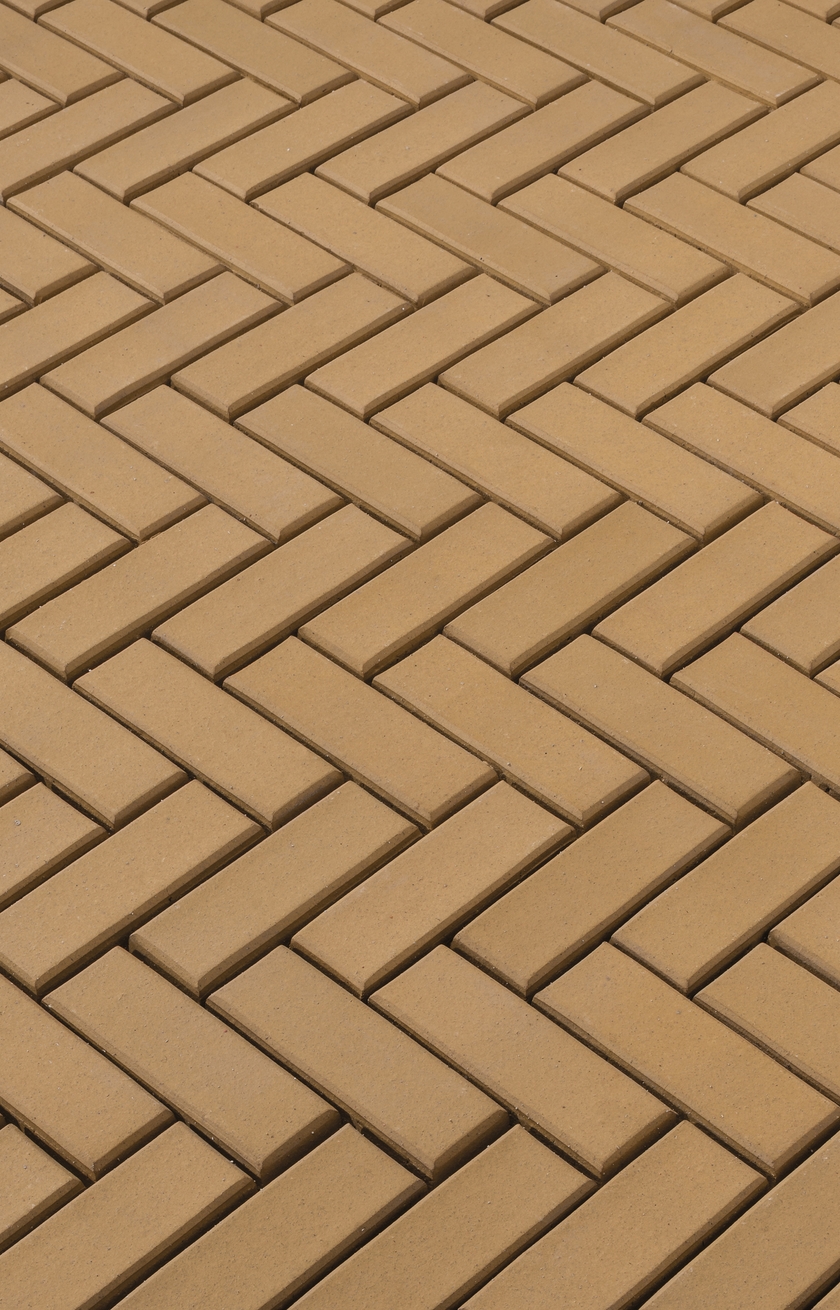

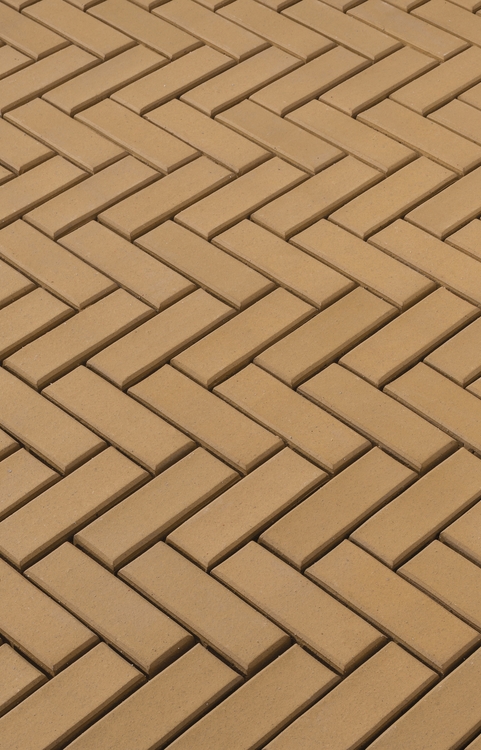

Extruded

We produce extruded bricks at our plants in Kessel and Oberlausitz.. A vacuum press produces a continuous clay beam with clean, rectangular dimensions. The beam is then cut into blocks of the correct size in a fully automatic process.

This production method lends itself well to different bricks types. We have eighteen standard sizes in our range, but we can deliver bespoke variants as well. You could opt for a tapered brick for example, or a brick with spaces. A chamfer is also possible. Extruded bricks have a naturally sleek appearance, but can be given a more rustic appearance through tumbling. As extruded pavers are largely made from primary clay, they are less porous than moulded bricks and can be supplied in bright colours.

Dimensionally stable, durable, and high-quality.

Moulded and extruded bricks each have their own unique character. An extruded brick is sleek or tumbled and available in bright colours. A moulded brick is more natural in shape and looks more authentic as a result. Whichever you opt for, clay pavers from Vandersanden are always dimensionally stable, sustainable, and of high quality.

The difference between moulded and extruded bricks

|

Moulded |

Extruded |

|---|---|

|

Natural appearance |

Sleek or rustic |

|

Ten sizes |

Eighteen standard sizes, bespoke sizes possible |

|

Natural colours (mixing possible) |

Including bright colours (mixing possible) |

|

Sand-covered: KOMO quality A4-12 E/EQ+ Unsanded: KOMO quality A4-12G |

KOMO quality A4-12 E/EQ+ |

|

Available in waal and dik size including with spacers, kei sizes always with chamfer |

Chamfer, taper, and spacers possible |

|

Stone can usually be reused on two or even three sides |

Stone cannot always be reused on two sides |